Overview

When the Niagara Power facility went on line in 1961, it emerged the largest hydropower facility in the Western world. For over a century, Niagara Falls remains as the cradle of great ideas about power generation and industrial utopias.

Its fame still echoes with a dedication speech given by President John F. Kennedy in White House, who declared this project as “a new and more prosperous era for the Niagara frontier” and “an example to the world of North American efficiency and determination.” This week we will introduce stainless steel applied in the Niagara Power Project.

The Project Information

The Niagara Project was launched as a replacement to the Schoellkopf Power Station destroyed by a catastrophic rockslide in June 1956. Robert Moses, New York's master builder, the head of the New York Power Authority (NYPA) then, led the project and one of the power plants named after him.

Located 4.5 miles downstream from Niagara Falls, the Niagara Project includes the Lewiston Pump Generating Plant, the Robert Moses Niagara Power Plant, two intake structures, two underground conduits and associated pump stations, a forebay, the Lewiston Reservoir, and the Niagara Switchyard.

The Obstacles

It was not until 18 March 1958 when the project was actually kicked off. There were obstacles on the way to its completion.

Firstly, the land to be expropriated was owned by the Tuscarora tribe who even resorted to lawsuit aiming to keep each acre of their land. In 1960, the U.S. Supreme Court ruled in favor of the NYPA, with $1,500 per acre compensated for 550 acres of the Tuscarora Reservation. It led to displacement of 175 members from the tribe and 37 of their homes.

Secondly, the project had death-related accidents due to the adverse geological conditions along the Niagara River gorge. During the construction, two giant trucks plunged into the river and 20 workers lost their lives in construction-related accidents.

The Success

Despite the obstacles, the project proved an unprecedented success. As mentioned earlier, it was the largest power generator in the Western world. To date, it remains New York’s largest electricity producer with a net dependable capability of 2.4MkW, sufficient to power nearly 2,000,000 families. After the construction of the Grand Coulee and Chief Joseph dams in Washington, it is still the third largest national wide.

The Niagara Power Project was a giant one as it involved 11700 employees with a cost of $737 million by the time it was built. Yet, with the engagement of the workers, the project was completed a bit ahead of schedule. The project produced its first power on 28 January 1961 and declared in full operation on 11 October 1962.

Stainless Steel Applied in the Niagara Power Project

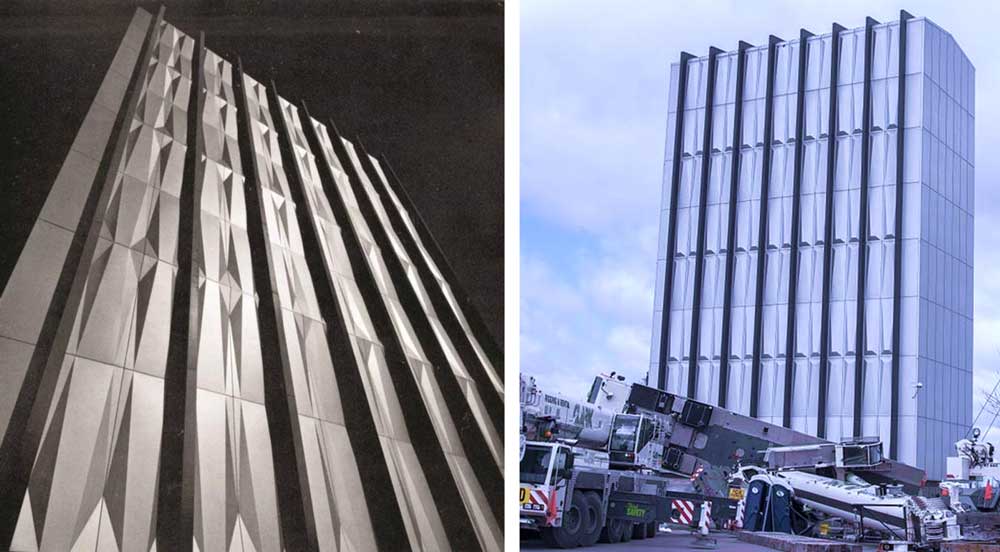

The 100-feet high intake structure, part of the whole system, is covered with stainless steel material as its curtain wall. There are two of them that hold the equipment allowing to adjust how much water flows over Niagara Falls.

Stainless Steel at CIVMATS

At CIVMATS, we stock famous brands stainless steel coils, ready for processing into cut-to-length stainless steel sheets and smaller stainless steel coils per your requirement.

Meanwhile, we also produce long stainless steel products, like stainless steel pipes tubes, stainless steel bars of varied shapes, stainless steel wires. If you are looking for a reliable stainless steel supplier from China, contact us for a free stainless steel solution. We are always here for you!