China Stainless Steel

Round Bar & Rod

As a leading Chinese stainless steel bar supplier, CIVMATS produce and manufacture a wide range of stainless steel round bars & rods.

Good Price

Top Quality

Custom Size

- CIVMATS

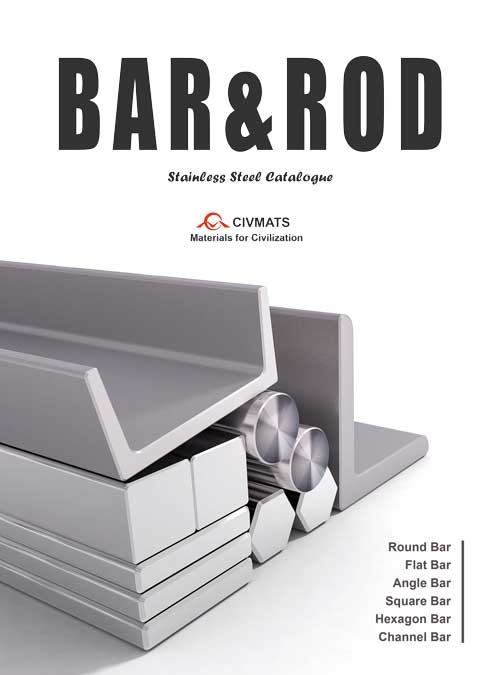

- Stainless Steel Bar & Rod

- Round Bar & Rod

Description

As a leading Chinese stainless steel bar supplier, CIVMATS produce and manufacture a wide range of stainless steel round bars & rods at both home and abroad. The supply of our SS round bars & rods comes with multiple sizes and various grades which are both customizable. Choose CIVMATS and find the best stainless steel round bars & rods. The customized length of stainless round bar is 5.8m, 6m, 4m and the like. Bright stainless steel round bar is cold drawn bar with its finish bright and smooth. Black bar stainless steel is hot rolled SS bar with black surface, or oxide skin produced after exposure to high temperature. Stainless steel round bars & rods (also titled stainless steel rods) are extensively used in fields such as kitchenware, shipbuilding, petrochemicals, equipment, medicine, food, electricity, energy, aerospace, construction and decoration, equipment under seawater, chemistry, dye, papermaking, oxalate, fertilizer production equipment, photography, coastland facilities, wire ropes, CD rod, screws and nuts.

Specifications

- • Diameter: 2mm-600mm

- • Delivery State: Cold Drawn, Hot Rolled, Forged, Grinding, Centerless Grinding

- • Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- • Hot-selling Products:

a. Stainless Steel Black Bar

b. Stainless Steel Bright Bar

c. S.S. Hot Rolled Round Bar

d. Stainless Steel Forged Bar - • Tolerance: h9, h11

Standards

- ASTM A276, ASTM A479, ASTM A484, ASTM A484M, DIN 671, DIN 1013, EN 10060, EN 10278, GB1220

Features

- Anti-corrosion (the degree is susceptible to the alloys contained), heat-resistance, good cold and hot working properties, good toughness, good comprehensive performances and wide application.

Applications

- Home appliances, electric appliances, construction materials, medical equipment, auto parts, petroleum, chemical application, agricultural irrigation, edible oil refinery factories, paper plants, shipyard, nuclear power plant etc.

Manufacturing Process

Drawing & Formula

Formula: m = OD (mm) × OD (mm) × L (m) × 0.00623

* For 400 series stainless steel, ratio=0.00609

OD = Outer diameter, L = Length

Size & Tolerance

| Size | Tolerance Rank | ||

|---|---|---|---|

| Group 1 | Group 2 | Group 3 | |

| >7 ~ ≤20 | ±0.25 | ±0.35 | ±0.40 |

| >20 ~ ≤30 | ±0.30 | ±0.40 | ±0.50 |

| >30 ~ ≤50 | ±0.40 | ±0.50 | ±0.60 |

| >50 ~ ≤80 | ±0.60 | ±0.70 | ±0.80 |

| >80 ~ ≤110 | ±0.90 | ±1.00 | ±1.10 |

| >110 ~ ≤150 | ±1.20 | ±1.30 | ±1.40 |

| Size | Tolerance Rank | |

|---|---|---|

| Group 1 | Group 2 | |

| >50 ~ ≤60 | +1.5 -1.0 | +2.0 -1.0 |

| >60 ~ ≤80 | +2.0 -1.0 | +2.5 -1.0 |

| >80 ~ ≤100 | +2.5 -1.0 | +3.0 -1.0 |

| >100 ~ ≤120 | +2.5 -1.5 | +3.0 -1.5 |

| >120 ~ ≤140 | +3.0 -1.5 | +3.5 -1.5 |

| >140 ~ ≤160 | +3.0 -2.0 | +4.0 -2.0 |

| >160 ~ ≤180 | +4.0 -2.0 | +5.0 -2.0 |

| >180 ~ ≤200 | +5.0 -2.0 | +6.0 -2.0 |

| >200 ~ ≤220 | +5.0 -3.0 | +6.0 -3.0 |

| >220 ~ ≤240 | +6.0 -3.0 | +7.0 -3.0 |

| >240 ~ ≤250 | +7.0 -3.0 | +8.0 -3.0 |

| >250 ~ ≤300 | +8.0 -3.0 | +9.0 -3.0 |

| Size | Tolerance Rank | |||||

|---|---|---|---|---|---|---|

| H8 | H9 | H10 | H11 | H12 | H13 | |

| 3 | 0 ~ -0.014 | 0 ~ -0.025 | 0 ~ -0.040 | 0 ~ -0.060 | 0 ~ -0.100 | 0 ~ -0.140 |

| >3 ~ ≤6 | 0 ~ -0.018 | 0 ~ -0.030 | 0 ~ -0.048 | 0 ~ -0.075 | 0 ~ -0.120 | 0 ~ -0.180 |

| >6 ~ ≤10 | 0 ~ -0.022 | 0 ~ -0.036 | 0 ~ -0.058 | 0 ~ -0.090 | 0 ~ -0.150 | 0 ~ -0.220 |

| >10 ~ ≤18 | 0 ~ -0.027 | 0 ~ -0.043 | 0 ~ -0.070 | 0 ~ -0.110 | 0 ~ -0.180 | 0 ~ -0.270 |

| >18 ~ ≤30 | 0 ~ -0.033 | 0 ~ -0.052 | 0 ~ -0.084 | 0 ~ -0.130 | 0 ~ -0.210 | 0 ~ -0.330 |

| >30 ~ ≤50 | 0 ~ -0.039 | 0 ~ -0.062 | 0 ~ -0.100 | 0 ~ -0.160 | 0 ~ -0.250 | 0 ~ -0.390 |

| >50 ~ ≤80 | 0 ~ -0.046 | 0 ~ -0.074 | 0 ~ -0.120 | 0 ~ -0.190 | 0 ~ -0.300 | 0 ~ -0.460 |

Delivery State

| Delivery State Choice | Surface Condition |

|---|---|

| Forged | Black |

| Polished | |

| Hot Rolled | Black |

| Polished | |

| Bright | |

| Pickled | |

| Cold Drawn | Polished |

| Bright | |

| Note: 1. If you require different deliver state than the above listed, kindly confirm with us. 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. |

|

Package

Plastic Bag

Wooden Pallet

In CIVMATS, all of our stainless steel round bars & rods are packaged as per international standard to prevent any possible damage or loss. By default, we will use thick woven plastic bag to bundle the finished pipes together in batches. However, for some special pipes that are vulnerable to dirt, scratches, stress or rough handling, we will suggest wooden case for protection. Kindly note, wooden case can incur extra cost, not only its own cost, but also the increased freight cost, which is especially true for air transportation. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Logistics

By Sea

By Air

By default, we will quote based on sea transportation, such as FOB, CFR, CIF and the like for most enquiries or orders. Quotation based on air transportation is also optional upon your request for urgent demands.

FAQ

Can you do SS grinding bar & rod?

Yes we can do SS grinding bar & rod featuring precise dimension, roundness and straightness, superior to stainless steel polished bars, but the processing cost is also higher.

What is Your MOQ (Minimum Order Quantity)?

Our MOQ is 1 ton. Larger quantity, lower price.

What is Your MOQ (Minimum Order Quantity)?

Normally 25 days, but it is also influenced by your specific requirements or the order quantity.

Is sample available?

Yes. For small piece, free sample of common size is available, but the freight will be yours to bear. For large sample, the sample cost paid will be deducted from the order amount. Please kindly confirm with our sales for your specific requirement.

Can I send our engineers to China?

Of course. Welcome to our factory for on-the-spot inspection.

How do you control the quality of your product?

Each production procedure will be subject to test and evaluation, from the very choice of the raw materials to the package for shipment. Only the products surviving all the tests are delivered for export.