China Stainless Steel

Thick-walled Pipe

As a leading Chinese stainless steel pipe & tubes supplier, CIVMATS produce and manufacture a wide range of stainless steel thick-walled pipe.

Factory Price

Top Quality

Custom Size

- CIVMATS

- Stainless Steel Pipe & Tube

- Thick-walled Pipe

Description

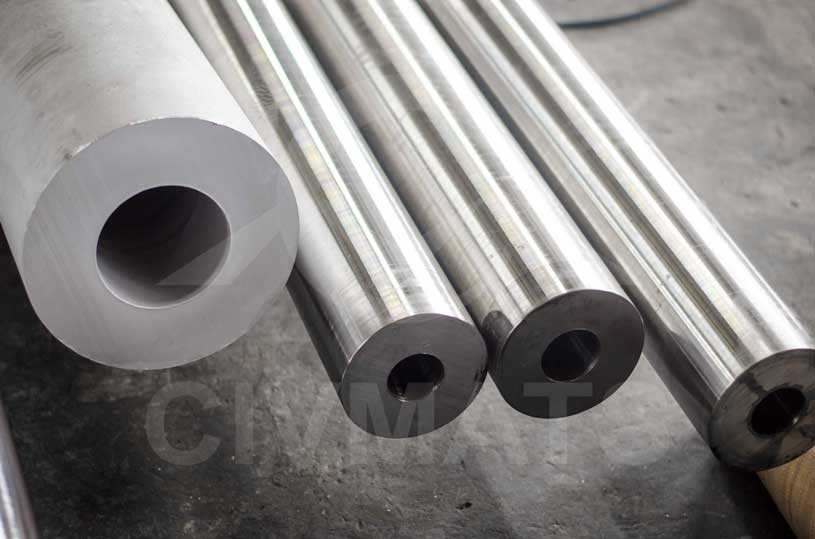

As a leading Chinese stainless steel pipe & tubes supplier, CIVMATS produce and manufacture a wide range of stainless steel thick-walled pipe. Thick-walled stainless steel pipe, also named stainless steel hollow bar, are usually used for mechanical applications or manufacturing hollow components such as nozzles, reducers, couplings etc. These applications always require corrosion-resistant or high-temperature strength. Thick-walled stainless steel pipes can be furnished in different shapes such as round, square, rectangular etc. while hollow bars are produced in round shape. The most common standard applied for thick-walled stainless steel pipe or hollow bar is ASTM A511 / A511M-16 which covers requirements for chemical compositions, mechanical properties and diameters. CIVMATS CO., LIMITED produces thick-walled stainless steel pipe strictly according to the standard under ISO 9001 system. Each product delivered from CIVMATS is a brand warrantee.

Specifications

- • Outer Diameter: Φ10-Φ1219mm (Minimum - Maximum)

- • Wall Thickness: SCH80S, SCH120, SCH160, XXS

- • *Customized size needs to be confirmed with us

Standards

- • American Standard: ASTM A312, ASME SA269, ASTM A269, ASME SA213, ASTM A213, ASTM A511, ASTM A789, ASTM A790, ASTM A376

- • Germany Standard: DIN2462.1-1981, DIN17456-85, DIN17458-85

- • European Standard: EN10216-5, EN10216-2

- • Japanese Standard: JIS G3463-2006, JIS G3459-2012

- • Russian Standard: GOST 9941-81

- • GB Standard: GB14975, GB14976, GB95, GB13296, GB5310, GB9948, GB/T12771

Features

- Anti-corrosion, high-pressure resistance, heat-resistance etc.

Applications

- Industrial application such as petroleum, chemical, fertilizer plants, energy, machinery application, boiler heat exchange and others

Manufacturing Process

Drawing & Formula

Formula: m = (OD - THK) × THK (mm) × L (m) × 0.02491

* For 316, 316L, 310S, 309S, etc., ratio=0.02507

OD = Outer diameter, THK = Wall Thickness, L = Length

Size Range

| Outer Diameter | Wall Thickness | Outer Diameter | Wall Thickness | Outer Diameter | Wall Thickness | Outer Diameter | Wall Thickness |

| 1/8 | 1 | 1 | 5 | 15/8 | 6 | 7/2 | 12 |

| 1/8 | 1.5 | 1 | 6 | 15/8 | 8 | 4 | 3 |

| 1/8 | 2 | 9/8 | 2 | 2 | 2 | 4 | 3.5 |

| 1/4 | 1 | 9/8 | 2.5 | 2 | 2.5 | 4 | 4 |

| 1/4 | 1.5 | 9/8 | 3 | 2 | 3 | 4 | 5 |

| 1/4 | 2 | 9/8 | 3.5 | 2 | 3.5 | 4 | 6 |

| 3/8 | 1 | 9/8 | 4 | 2 | 4 | 4 | 8 |

| 3/8 | 1.5 | 9/8 | 5 | 2 | 5 | 4 | 10 |

| 3/8 | 2 | 9/8 | 6 | 2 | 6 | 4 | 12 |

| 3/8 | 2.5 | 5/4 | 2 | 2 | 8 | 5 | 4 |

| 3/8 | 3 | 5/4 | 2.5 | 2 | 10 | 5 | 5 |

| 7/16 | 2 | 5/4 | 3 | 2 | 12 | 5 | 6 |

| 7/16 | 2.5 | 5/4 | 3.5 | 9/4 | 2 | 5 | 8 |

| 7/16 | 3 | 5/4 | 4 | 9/4 | 2.5 | 5 | 10 |

| 7/16 | 3.5 | 5/4 | 5 | 9/4 | 3 | 5 | 12 |

| 7/16 | 4 | 5/4 | 6 | 9/4 | 3.5 | 6 | 4 |

| 1/2 | 2 | 11/8 | 2 | 9/4 | 4 | 6 | 5 |

| 1/2 | 2.5 | 11/8 | 2.5 | 9/4 | 5 | 6 | 6 |

| 1/2 | 3 | 11/8 | 3 | 9/4 | 6 | 6 | 8 |

| 1/2 | 3.5 | 11/8 | 3.5 | 9/4 | 8 | 6 | 10 |

| 1/2 | 4 | 11/8 | 4 | 9/4 | 10 | 6 | 12 |

| 5/8 | 2 | 11/8 | 5 | 9/4 | 12 | 8 | 4 |

| 5/8 | 2.5 | 11/8 | 6 | 5/2 | 3 | 8 | 5 |

| 5/8 | 3 | 3/2 | 2 | 5/2 | 3.5 | 8 | 6 |

| 5/8 | 3.5 | 3/2 | 2.5 | 5/2 | 4 | 8 | 8 |

| 5/8 | 4 | 3/2 | 3 | 5/2 | 5 | 8 | 10 |

| 3/4 | 2 | 3/2 | 3.5 | 5/2 | 6 | 8 | 12 |

| 3/4 | 2.5 | 3/2 | 4 | 5/2 | 8 | 10 | 6 |

| 3/4 | 3 | 3/2 | 5 | 5/2 | 10 | 10 | 8 |

| 3/4 | 3.5 | 3/2 | 6 | 5/2 | 12 | 10 | 10 |

| 3/4 | 4 | 3/2 | 8 | 3 | 3 | 10 | 12 |

| 3/4 | 5 | 7/4 | 2 | 3 | 3.5 | 12 | 10 |

| 3/4 | 6 | 7/4 | 2.5 | 3 | 4 | 12 | 12 |

| 7/8 | 2 | 7/4 | 3 | 3 | 5 | 14 | 10 |

| 7/8 | 2.5 | 7/4 | 3.5 | 3 | 6 | 14 | 12 |

| 7/8 | 3 | 7/4 | 4 | 3 | 8 | 16 | 10 |

| 7/8 | 3.5 | 7/4 | 5 | 3 | 10 | 16 | 12 |

| 7/8 | 4 | 7/4 | 6 | 3 | 12 | 18 | 10 |

| 7/8 | 5 | 7/4 | 8 | 7/2 | 3 | 18 | 12 |

| 7/8 | 6 | 15/8 | 2 | 7/2 | 3.5 | 20 | 10 |

| 1 | 2 | 15/8 | 2.5 | 7/2 | 4 | 20 | 12 |

| 1 | 2.5 | 15/8 | 3 | 7/2 | 5 | 24 | 10 |

| 1 | 3 | 15/8 | 3.5 | 7/2 | 6 | 24 | 12 |

| 1 | 3.5 | 15/8 | 4 | 7/2 | 8 | ||

| 1 | 4 | 15/8 | 5 | 7/2 | 10 |

Delivery State

| Delivery State Choice | Surface Condition |

|---|---|

| Hot Rolled | Pickled |

| Sand Blasted | |

| Annealed | Pickled |

| Sand Blasted | |

| Note: 1. If you require different deliver state than the above listed, kindly confirm with us. 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. |

|

Package

Plastic Bag

Wooden case

In CIVMATS, all of our stainless steel thick-walled pipes are packaged as per international standard to prevent any possible damage or loss. By default, we will use thick woven plastic bag to bundle the finished pipes together in batches. However, for some special pipes that are vulnerable to dirt, scratches, stress or rough handling, we will suggest wooden case for protection. Kindly note, wooden case can incur extra cost, not only its own cost, but also the increased freight cost, which is especially true for air transportation. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Logistics

By Sea

By Air

By default, we will quote based on sea transportation, such as FOB, CFR, CIF and the like for most enquiries or orders. Quotation based on air transportation is also optional upon your request for urgent demands.

FAQ

What standard do you follow for the thick-walled SS pipes?

The common standard for stainless steel thick-walled pipe or stainless steel hollow bar we follow is ASTM A511. Unlike fluid-carrying seamless tubes, these SS thick-walled pipes are for use in mechanical applications or as hollow bar for use in the production of hollow components such as, but not limited to nozzles, reducers, and couplings by machining where corrosion-resistant or high-temperature strength is needed.

Can you do polishing to these SS thick-walled pipes?

Yes, we can polish these pipes into 200 to 600 grit as per your requirement. We can also polish 8K/mirror finish.

What's the main grade of thick-walled SS pipes?

MT 321, MT 347, MT 316(L), MT 309S, MT 310S, MT 304(L).

What's your standard package?

we will use thick woven plastic bag to bundle the finished SS pipes together in batches.

What's your standard length?

Random length, 1.5m, 2m, 3m, 4m, 5m, 6m or customized.

What's your main market?

South America, Middle East, Southeast Asia etc.