Overview

Stainless steel has become a nearly ubiquitous part of our day-to-day lives, from what we use, where we work to how we travel. They are applied into appliances, buildings, and transportation vehicles. Previously we have introduced the stainless steel used in architecture, mostly chosen as the skin material. This week we will introduce stainless steel used as the steel framework through the case of the world famous Statue of Liberty.

The Gift from France

The statue of liberty, also known as the Liberty Enlightening the World or Statue of Liberty National Monument, is a gift from France and shipped to USA by ship in June 1885. It turns out to be the New York’s most iconic landmark, symbolizing freedom, inspiration, and hope.

This monument was originally the idea of a French poet and antislavery activist named Édouard de Laboulaye, who proposed it in 1865. He believed celebrating American’s centennial of independence after the Civil War and the abolition of slavery could also consolidate France’s democratic ideals.

Frédéric Auguste Bartholdi, the young French sculptor proved an ardent supporter of Laboulaye’s idea with his final version of design patented in 1879. Eugene Viollet-le-Duc, the statue’s engineer died prior to the completion of the inside of the sculpture. Alexandre Gustave Eiffel, the designer of the Eiffel Tower, was then hired to design the statue’s skeletal framework and engineer the project.

The Background Information

The statue of Liberty is located on Liberty Island (previously known as Bedloe's Island) in New York, emerging from the waters of New York Harbor to greet immigrants who originally came to the country through nearby Ellis Island. Bartholdi paid a visit to USA in 1871 when he was designing the statue. He chose this site because he regarded the island as the "gateway to America." Small as it was, every ship entering New York Harbor could see it.

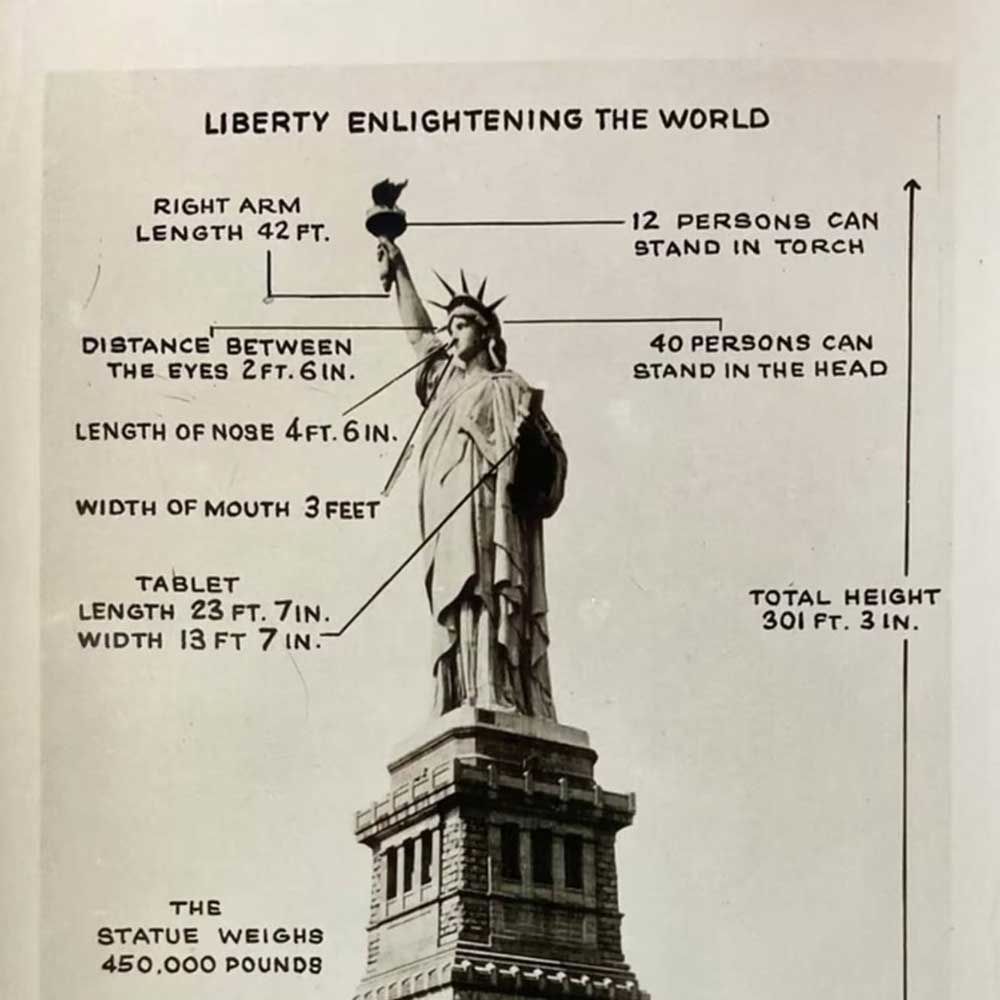

The Statue of Liberty impresses us with a crowned woman holding a torch in her raised right hand, a tablet bearing the adoption date of the Declaration of Independence (July 4, 1776) in her left and a broken shackle and chains at her foot. It is consisted with two parts, the statue of Lady Liberty herself and the pedestal where she stands.

The whole monument was a teamwork of France and America, representing their friendship as well. The fundraising and construction of the statue of Lady Liberty was conducted in France while the pedestal completed in USA. Due to the fundraising issues arising during the pedestal construction, the whole project was delayed. The statue of Lady Liberty was completed in France as early as in July 1884, but the monument was dedicated by President Grover Cleveland over two years later on 28 October 1886.

The Statue of Liberty

The Statue of Liberty was designed huge, larger than any other sculptures worldwide by that time. It stands 93 meters high from the base to the tip of torch, with the figure of Lady Liberty 46 meters high and the pedestal 47 meters high.

As impressive as the height is the weight. The statue of Lady Liberty alone weighs roughly 225 tons with the skin weighing about 31 tons and the internal steel structure nearly 125 tons. The pedestal and foundation add extra 54,000 tons to the monument.

The Materials Applied in The Statue of Lady Liberty

The Cooper Skin & the Iron Framework

The Statue of Lady Liberty is covered with 2.4mm thick brown copper as the skin. Inside the statue was the iron framework designed by Eiffel whose structural-engineering expertise was vital to keep the statue upright and secure, allowing the exterior copper sway slightly in the wind independently without the threat of deformation or instability in strong winds.

The Statue of Liberty’s copper skin was originally brown-colored, but with years’ natural weathering it changed into its now iconic green patina. The thin layer of oxidation prevents the copper from erosion over time.

The Stainless Steel Applied in Restoration

Although Bartholdi and Eiffel considered the potential risk of electrochemical corrosion at the design stage and harnessed electrical insulating material subsequently, the measures failed to prevent salty moisture and acid rain from penetrating inside the cooper skin.

By 1981, the electrochemical corrosion accelerated to such a degree that the copper suffered from severe corrosion. In order to restore this historic heritage for its centennial celebration, the renovation and repair work has been proposed to agenda in 1982 and completed in 1986.

The torch was deteriorated beyond repair and replaced with a replica that followed Bartholdi’s design with repoussé copper sheathed in gold leaf. The deteriorating internal iron frame was replaced with stainless steel 316L and duplex stainless steel.

Stainless steel 316L and duplex stainless steel are both ideal materials to resist corrosion from salty water and acid rain. The difference lies in mechanical property as duplex stainless steel has almost twice strength than that of 316L in similar size. The combination of both stainless steel materials can optimize the performance and cost.

Stainless steel outperforms the iron steel as the framework for even further advantages. 1) The galvanic corrosion doesn’t occur between copper and stainless steel. 2) Copper and stainless steel share the same coefficient of thermal expansion. This replication of material guarantees the Statue of Liberty to shine its former glory for longer service life.

Stainless Steel Materials at CIVMATS

If you are in demand for stainless steel bars, stainless steel tubes and stainless steel sheets to support as internal structure for your stainless steel projects, welcome to CIVMATS. We offer the greatest value for your choice!