Overview

Last week we have introduced the reasons why stainless steel is the ideal material for bridge construction. This week let us resume our exploration into the world of stainless steel through the case of the Go Between Bridge in Brisbane, Australia.

The Go Between Bridge

The Go Between Bridge as part of the Hale Street Link project was initially known as the Hale Street Link. It was later changed to the Go Between Bridge in recognition of the popular Brisbane indie rock band The Go-Betweens after a 'name-the bridge' Internet contest.

The construction of the bridge was commenced in 2008 and completed in 2010. It was officially opened to traffic on 5 July 2010 with a cost of $338 million. Robert Forster, the former member of The Go-Betweens, even performed on the bridge to celebrate its completion and raise money for charity (Weekend Notes, 2025).

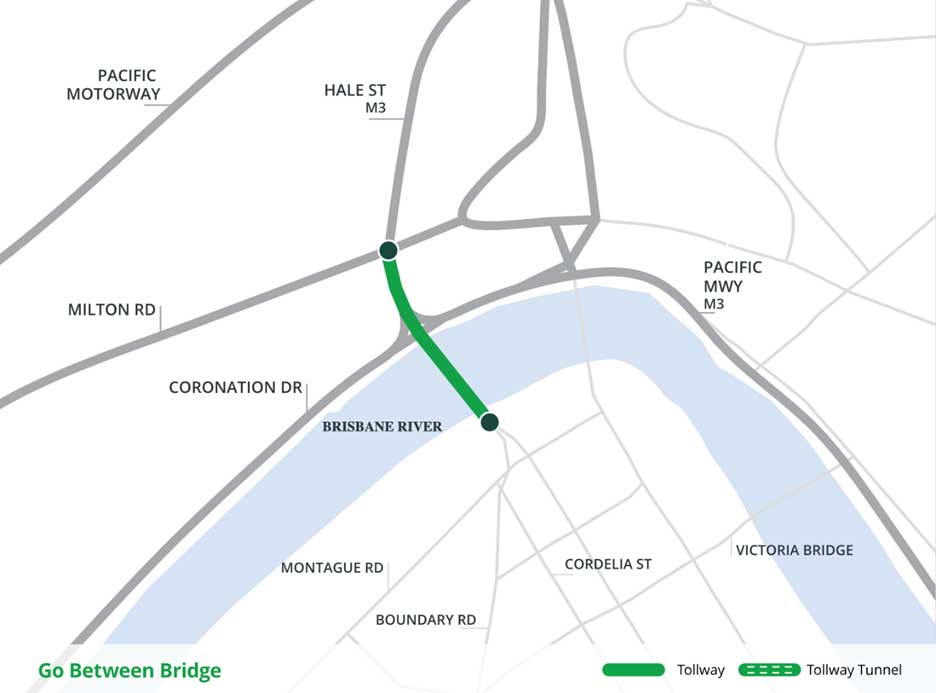

The Go Between Bridge connects Merivale and Cordelia Streets in West End to Hale Street and the Inner City Bypass at Milton, providing an alternative to the William Jolly Bridge. It starts from Kurilpa Park on the South Brisbane side and Coronation Drive on the other. The bridge carries approximate 14,000 vehicles each day.

The Design of The Go Between Bridge

The Go Between Bridge boasts the Brisbane’s first integral inner-city river crossing bridge in 40+ years. It was designed to enhance cross-river convenience, ease inner city traffic congestion, increase accessibility to Brisbane’s recreational, educational and cultural precincts and promote future residential developments in West End and South Brisbane (ASSDA, 2025).

The Go Between Bridge is a four-lane, three-span, 274-meters long, 27-meters wide, pre-stressed segmental box, two-pier concrete balanced cantilever bridge over the Brisbane River. It is a toll bridge for pedestrians, cyclists as well as vehicles crossing the Brisbane River with a central span of 117m, featuring two separate bicycle and pedestrian paths.

Stainless Steel Applied in the Go Between Bridge

The Go Between Bridge is mainly constructed with stainless steel and concrete. Stainless steel as the reinforcement material plays an important role in bridge structure. There are 80 tons of 316L stainless steel rebar used in the bridge. These Reval® stainless steel rebars are supplied by Valbruna Australia in diameter 12mm, 16mm, and 24mm.

With stainless steel specified, the life cycle costs of the bridge can be reduced to the lowest. Firstly, 316L stainless steel was selected for its excellent resistance to the chlorides and pitting corrosion from the marine environment. This can undoubtedly extend the bridge service life and ensure longevity for public infrastructure. Secondly, stainless steel rebar possesses higher tensile strength than carbon steel, which means it can reduce the aera where the stainless steel rebar should be used. Hence, it could save cost as less material was needed. Thirdly, applying stainless steel reinforcement in concrete structures is stronger than using carbon steel. It can thus prevent material fatigue and keep the structure integrity over its long service life.

Stainless Steel Rebars at CIVMATS

At CIVMATS, we have huge stock of stainless steel round bars which can be readily processed into stainless steel rebars per your requirement. Grades, dimensions and/or finishes are customizable per your specific project demand.

If you are looking for good quality stainless steel rebar from China, whether in grade 304, 316(L), 321 or 310S, welcome to CIVMATS for free consultation. We aim for the best value for each of your stainless steel material choice. Choose CIVMATS, choose reliability.