Overview

Thin-walled stainless steel tubes are typically made by welded process. Even for making welded tubes, the wall thickness is hardly below 0.5mm in most cases, even for food industry. However, in certain industries, stainless steel tubes are required to be 1) incredibly thin and 2) seamless at the same time. This week we will introduce ultra-thin stainless steel seamless tubes, because many clients still don’t know where to source this niche product safely in China.

The Market

Certain industries like aerospace and luxury cars are in the market for ultra-thin stainless steel seamless tubes. These tubes are light-weighted, corrosion resistant, temperature resistant and pressure resistant, extremely suitable for transportation tools.

With the development of auto industry and aerospace industry, we hereby introduce our high quality seamless stainless steel ultra-thin tubes produced per GB/T 3089. A step forward to the rising demand of high-end material ultra-thin seamless stainless steel tubes.

What is Ultra-thin Stainless Steel Seamless Tube?

Ultra-thin stainless steel seamless tubes are those stainless steel tubes which thicknesses are inappropriately smaller in corresponding to their outside diameters, supplied in seamless form. To understand this, it is necessary to make a reference to ANSI B36.10 / B36.19 where standard tube sizes are listed.

According to ANSI B36.10 / B36.19, SCH5S is the smallest wall thickness, mostly used for welded tubes. For seamless tubes, it has to start from wall thickness SCH10S. Ultra-thin stainless steel seamless tubes has wall thickness smaller than SCH5S. For better understanding, let us see the data first as below table excerpted from ANSI B36.10 / B36.19.

| Nominal Tube Size | OD | SCH5/5S | SCH10S | |

|---|---|---|---|---|

| NPS | DN | mm | mm | mm |

| 1/8 | 6 | 10.3 | / | 1.24 |

| ¼ | 8 | 13.7 | / | 1.65 |

| 3/8 | 10 | 17.1 | / | 1.65 |

| ½ | 15 | 21.3 | 1.65 | 2.11 |

| ¾ | 20 | 26.7 | 1.65 | 2.11 |

| 1 | 25 | 33.4 | 1.65 | 2.77 |

| 5/4 | 32 | 42.2 | 1.65 | 2.77 |

| 3/2 | 40 | 48.3 | 1.65 | 2.77 |

| 2 | 50 | 60.3 | 1.65 | 2.77 |

| 5/2 | 65 | 73 | 2.11 | 3.05 |

| 3 | 80 | 88.9 | 2.11 | 3.05 |

| 7/2 | 90 | 101.6 | 2.11 | 3.05 |

| 4 | 100 | 114.3 | 2.11 | 3.05 |

| 5 | 125 | 141.3 | 2.77 | 3.40 |

| 6 | 150 | 168.3 | 2.77 | 3.40 |

| 8 | 200 | 219.1 | 2.77 | 3.76 |

Ultra-thin Stainless Steel Seamless Tube Dimensions

Our excerption is listed up to DN200 (219.1mm) within which our production scope falls. SCH5S is always for stainless steel welded tube and SCH10S for stainless steel seamless tube, both listed for straight-forward comparison. Our ultra-thin stainless steel seamless tube dimensions are as below.

- OD: Ø3 MM - Ø219.1 MM

- WT: 0.2 MM - 3.05 MM

- OD×WT: Customizable

(Customizable, take OD 60.2 MM * WT 0.2 MM * L 178 MM for instance, as below photo illustrated, it is used as part of the final product and the client will weld caps and dent it by themselves)

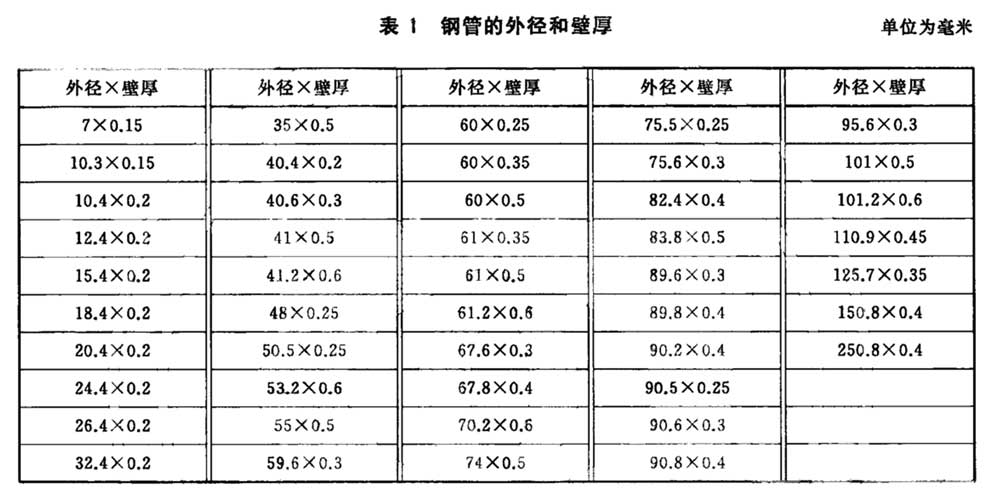

Below table listed are the regular sizes of ultra-thin stainless steel seamless tubes excepted from GB/T 3089. The sizes are depicted in the form of OD×WT in unit millimeter.

Below is ultra-thin stainless steel seamless tube OD tolerance specified by GB/T 3089.

| OD (mm) | Acceptable Tolerance (mm) | |

|---|---|---|

| Generally Accepted* | Advanced | |

| ≦12.4 | ±0.10 | ±0.08 |

| >12.4~32.4 | ±0.15 | ±0.10 |

| >32.4~60 | ±0.15 | ±0.25 |

| >60 | ±1% | ±0.75% |

*Unless advanced OD tolerance is clearly specified in the contract, otherwise the order will be executed per generally accepted tolerance on the left size of the advanced tolerance.

Below is ultra-thin stainless steel seamless tube WT tolerance specified by GB/T 3089.

| Tube Size | Acceptable Tolerance (mm) | ||

|---|---|---|---|

| For OD (mm) | WT (mm) | Generally Accepted* | Advanced |

| ≦60 | ≦0.20 | ±0.03 | +0.03 -0.01 |

| 0.25 | +0.04 -0.03 |

+0.03 -0.02 |

|

| 0.30 | ±0.04 | ±0.03 | |

| 0.35 | +0.05 -0.04 |

+0.04 -0.03 |

|

| 0.40 | ±0.05 | ±0.04 | |

| 0.50 | ±0.06 | +0.05 -0.04 |

|

| 0.60 | ±0.08 | ±0.05 | |

| >60 | ≦0.25 | ±0.04 | ±0.03 |

| 0.30 | ±0.04 | +0.04 -0.03 |

|

| 0.35 | ±0.05 | ±0.04 | |

| 0.40 | ±0.05 | +0.05 -0.04 |

|

| 0.45 | ±0.06 | ±0.05 | |

| 0.50 | ±0.06 | ±0.05 | |

| 0.60 | ±0.08 | ±0.05 | |

| >0.60~0.80 | ±0.10 | ±0.06 | |

| >0.80~1.0 | ±0.12 | ±0.08 | |

| >1.0 | ±0.15 | ±0.10 | |

*Unless advanced WT tolerance is clearly specified in the contract, otherwise the order will be executed per generally accepted tolerance on the left size of the advanced tolerance.

Ultra-thin Stainless Steel Seamless Tube Length Tolerance

Generally, length is 800~6000MM in range. Length is customizable, with the tolerance accepted at +10mm, -0mm.

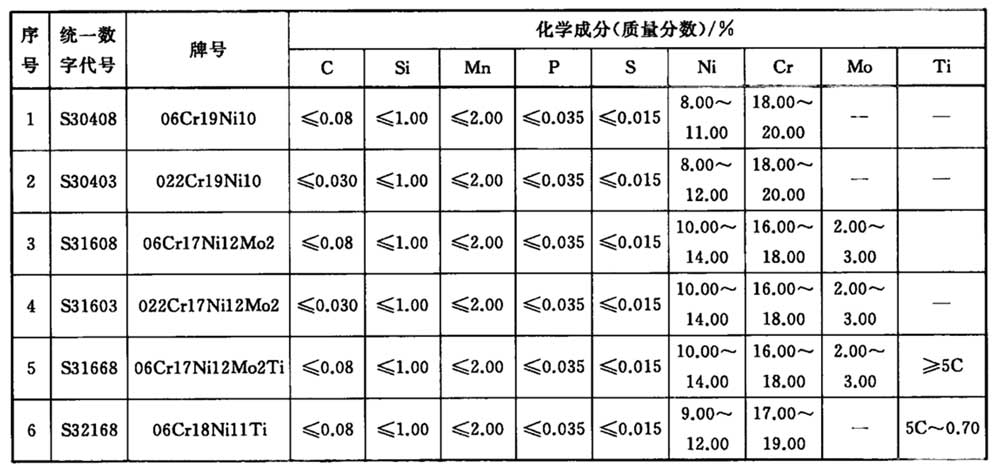

Ultra-thin Stainless Steel Seamless Tube Grades Available

Ultra-thin stainless steel seamless tubes are supplied in austenitic 304 (S30408), 304L (S30403), 316 (S31608), 316L (S31603), 321 (S32168), 316Ti (S31668) as below listed.

How Ultra-thin Stainless Steel Seamless Tube is Different?

Apart from the above mentioned difference in wall thickness, the melting method and process of ultra-thin stainless steel seamless tubes are divergent from traditional standard-size stainless steel seamless pipes.

• Melting Methods

Ultra-thin stainless steel seamless tubes are produced with the melting methods clearly specified by GB/T 3089. Double-melt methods like VIM+ESR are required to ensure the steel purity. Even advanced double-melt methods can be negotiated and agreed between buyer and seller.

• Process

Ultra-thin stainless steel seamless tubes are produced by spin forming or cold rolled (drawn) method.

Ultra-thin Stainless Steel Seamless Tube At CIVMATS China

If you are looking for ultra-thin stainless steel seamless tubes from China, come to CIVMATS. We produce aviation-specific ultra-thin stainless steel seamless tubes at highest standard, safe and reliable. High quality for long-term supply. Choose CIVMATS, choose reliability.