Due to excellent corrosion resistance, strength, toughness, durability, aesthetic appeal, easy construction, easy maintenance, long service life and environmental friendliness, stainless steel as construction material has enjoyed wide popularity. Since the year 2000, stainless steel has been increasingly applied in varied fields, including bridge construction. Let’s explore the stainless steel applied in bridge building by the case study of Gateway Bridge in Brisbane Australia.

The Gateway Bridge crossing the Brisbane River is located in Queensland, Australia, financed by funds borrowed from Queensland Government. Users of the bridge pay a toll on the southern side of the river. The construction commenced on 5 June 1980, open to the public on 11 January 1986. It was the first of its kind in terms of its unique structure (the main 260-meters – span was concrete free) and kept the record for over 15 years. To accommodate the air traffic nearby and shipping requirements, the bridge was shaped distinctively.

In 2005, the construction of 2nd Gateway Bridge a few meters away was announced for an expansion of the original four-lane motorway to the six-lane. It was a duplication to the first one as it took the same shape. Design and construction work were dundertaken by Queensland Motorways and maintenance work by the Leighton Abigroup Joint Venture (LAJV). The upgrade was a $1.88 billion project with a design life for 300 years. Stainless steel materials, hence, came into play without exception. It was duplex stainless steel LDX 2101 reinforcement bar from Outokumpu Group.

Duplex stainless steel features excellent corrosion resistance while has almost twice strength as that of austenitic 300 series. It is understandably more expansive than common 300 series, however the cost from better material is mitigated by using less. Due to the higher strength, duplex stainless steel can do the same work as that of austenitic stainless steels with smaller size (or less material). It is undoubtedly an economic effective choice from a long-term investment perspective for many reasons.

Minimizing maintenance frequency can reduce the cost, material resources and manpower required. Above all, it can delay replacement and avoid unnecessary disruption caused by the maintenance activities, which can prevent the project owner from receiving continuous revenue and meanwhile bring inconvenience to the users. Double harms at the same time. Designing for a long service life can reduce harms to the environment, minimize pollution to the local communities and can therefore be regarded as more environment friendly. A durable project like The Gateway Bridge in Australia can be a good reference for future projects in experience and strategic choice of raw materials.

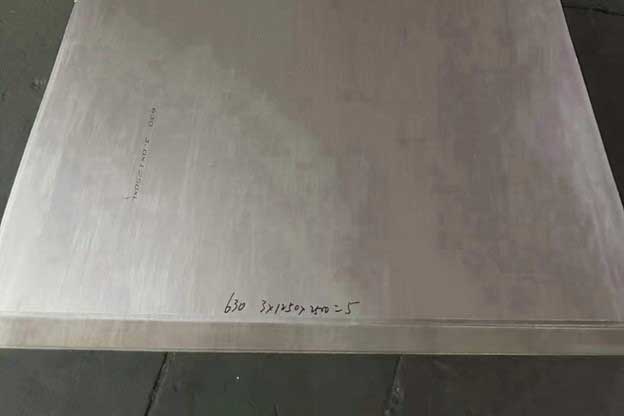

At Civmats, we can produce stainless steel rebars (stainless steel reinforcement bar) as per your specific project demands. Whether you are after common stainless steel grades 304(L), 316(L) or special stainless steel grades like duplex 2205, high-temperature resistant grade 310S, we can customize as per your specific needs. Sizes are also customizable. Welcome for consultation for free.