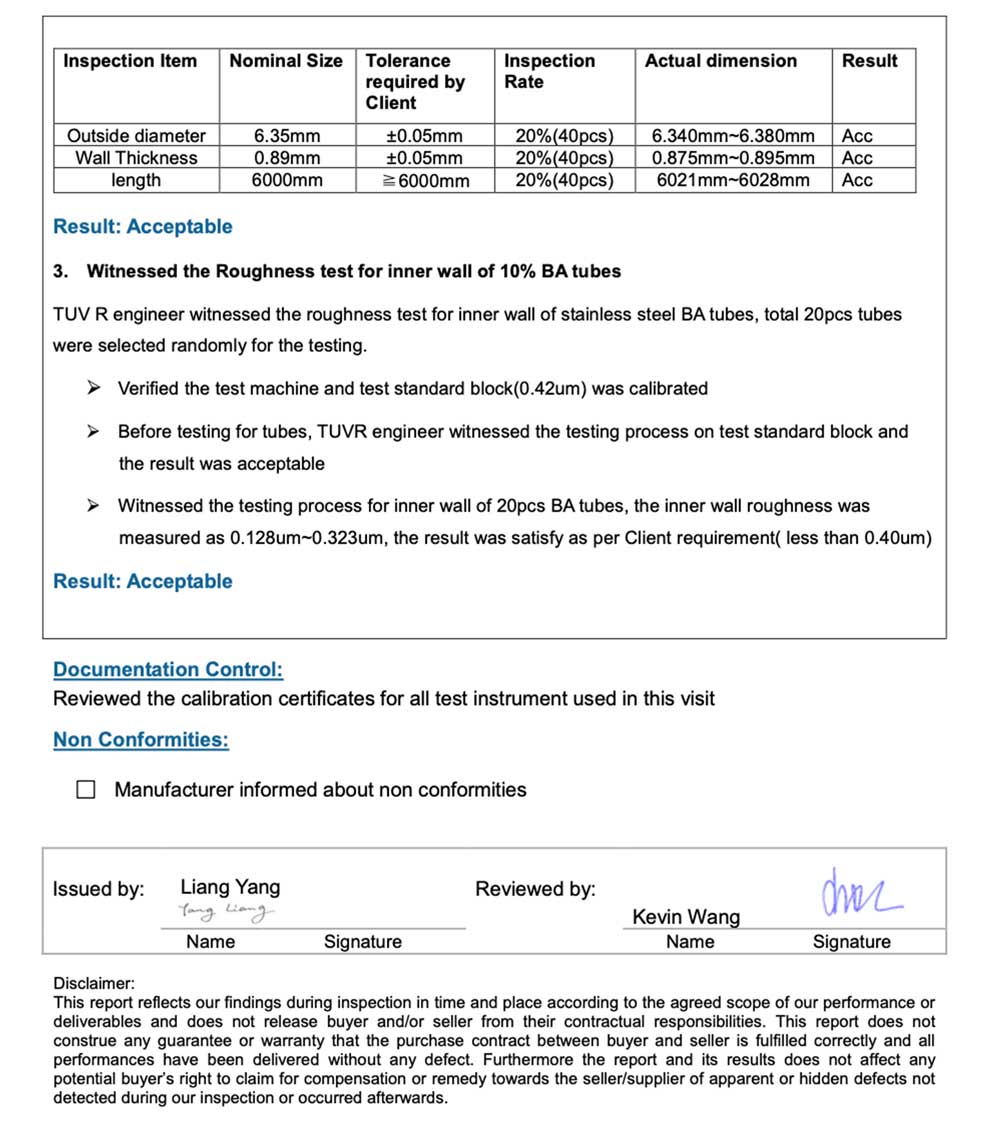

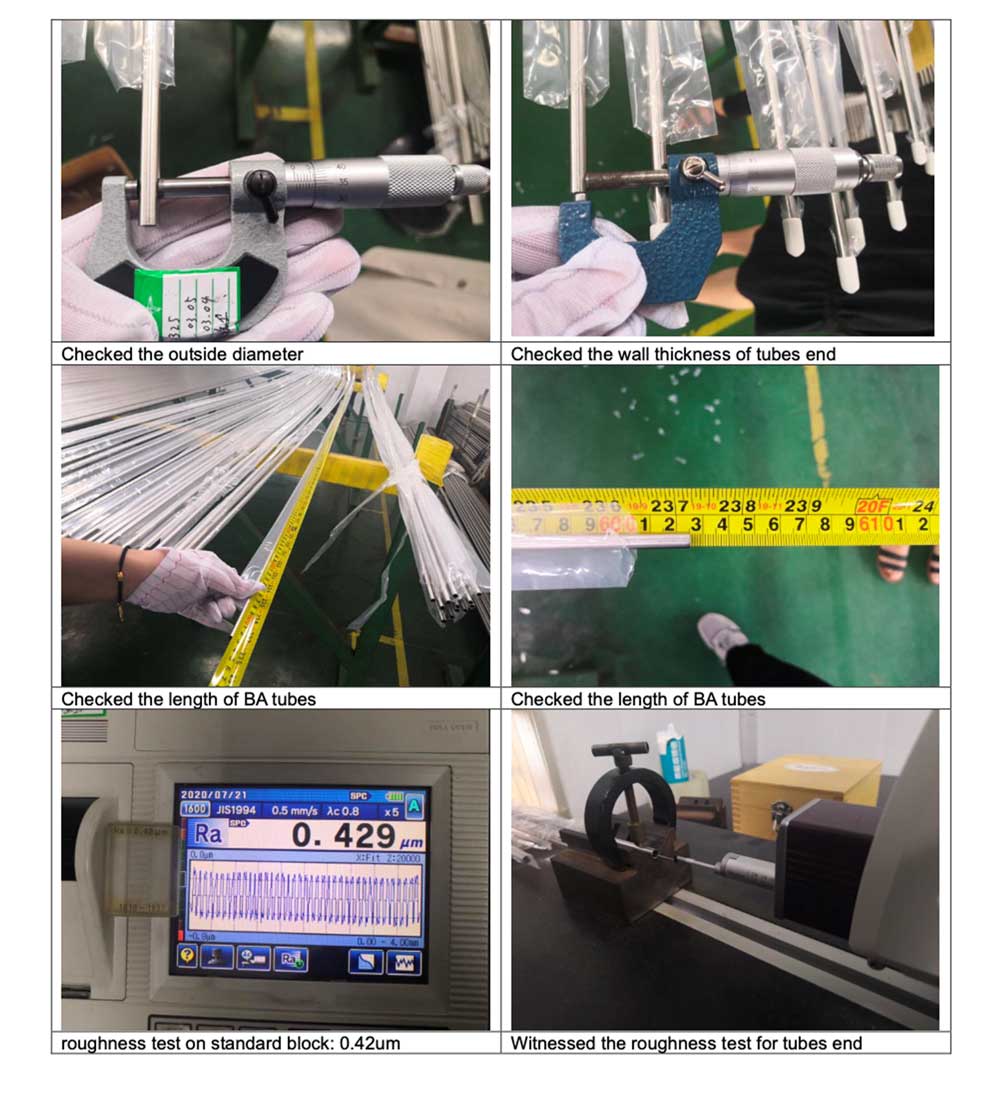

Overview

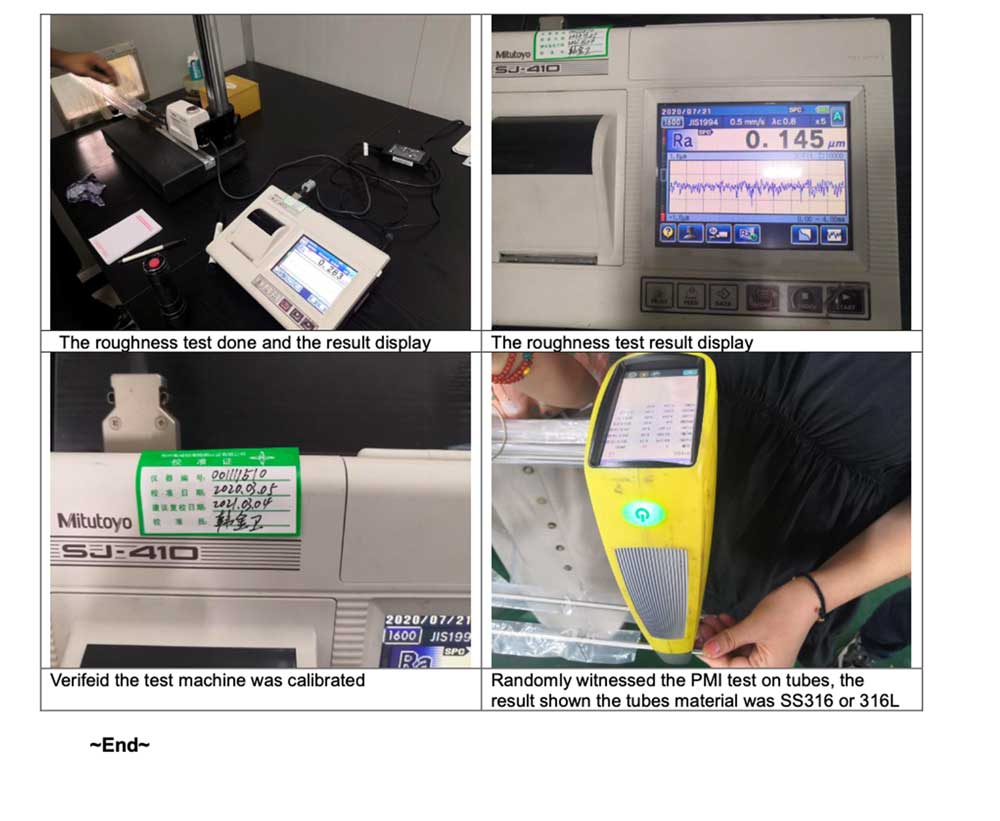

Electropolished stainless steel tube is also known as EP stainless steel tubing. For high demanding industries where the tube finish smoothness, brightness and cleanliness matter, EP stainless steel tubing comes into play. The electropolishing process gives rise to the finest surface with the internal Ra value controllable below 0.25um. At CIVMATS, we can achieve an internal roughness at 0.145um as inspected by TUV report.

Unlike traditional process of cutting heads and ends, the EP tubes are cut with waterjet, minimizing the contamination from the very start. Ultrasonic cleaning (USC), ultra-high purity (UHP) nitrogen drying, and packed in clean room make sure the highest standard of cleanliness. Clean room EP stainless steel tubing is commonly used for carrying pure gas, food & beverage, pharmaceutical and semiconductor industries with heightened cleanliness and smoothness.

What is EP Stainless Steel Tubing?

EP stainless steel tubing is the cleanest stainless steel tube with the highest standard requirement on internal roughness, which BA cannot even compare. At CIVMATS, our EP stainless steel tubing can achieve 0.25um below in terms of roughness while BA stainless steel tubes at 0.4um below (superior to industrial average 0.5um below).

Dimensions

- OD: ¼" (6.35mm) ~ 2" (50.8mm)

- WT: 0.035" (0.89mm) ~ 0.065" (1.65mm)

| OD * WT | |||||||

|---|---|---|---|---|---|---|---|

| ¼" (6.35mm) * 0.89mm | 12.0mm * 1.00mm | 1" (25.4mm) * 1.24mm | |||||

| 6.0mm * 0.89mm | 1/2" (12.7mm) * 1.00mm | 1" (25.4mm) * 1.65mm | |||||

| ¼" (6.35mm) * 1.00mm | 1/2" (12.7mm) * 1.24mm | ||||||

| 1/2" (12.7mm) * 1.65mm | 1 1/4" (31.8mm) * 1.65mm | ||||||

| 3/8" (9.53mm) * 0.89mm | |||||||

| 3/8" (9.53mm) * 1.00mm | 3/4" (19.05mm) * 1.24mm | 1 1/2" (38.1mm) * 1.65mm | |||||

| 10.0mm * 1.00mm | 3/4" (19.05mm) * 1.65mm | ||||||

| 19.0mm * 1.50mm | 2" (50.8mm) * 1.65mm | ||||||

| 23.0mm * 1.50mm | |||||||

Specifications

- ASTM A269

- ASTM A213

- ASTM A632

- ASTM A262

- ASTM A1016

Grades

TP 304, TP316, TP316L

| Grade | Chemical Compositions (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Si | Ni | Cr | Mo | |

| TP304 | ≦0.08 | ≦2.00 | ≦0.045 | ≦0.030 | ≦1.00 | 8.0-12.0 | 18.0-20.0 | / |

| TP316 | ≦0.08 | ≦2.00 | ≦0.045 | ≦0.030 | ≦1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 |

| TP316L | ≦0.035 | ≦2.00 | ≦0.045 | ≦0.030 | ≦1.00 | 10.0-15.0 | 16.0-18.0 | 2.00-3.00 |

| Grade | Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPA) | Yield Strength (MPA) | Elongation (%) | Hardness (HRB) | |||||

| TP304 | ≧515 | ≧205 | ≧35 | ≦90 | ||||

| TP316 | ≧515 | ≧205 | ≧35 | ≦90 | ||||

| TP316L | ≧485 | ≧170 | ≧35 | ≦90 | ||||

Why EP Stainless Steel Tubing?

From the choice of raw material to the package at clean room, the EP stainless steel tube are least exposed to any contamination through the whole process. The waterjet cutting process prevents not only the sparks generated by thermal cutting but also dust from the grinding wheel cutting. Soaked in specialized medicament for 2 hours, the tubes are degreased further through automated cleaning process with both medicament and pure water for a total of 1 hour.

Electropolishing process involves polishing the stainless steel tubes through electrolyte and electricity which differentiates it from simple chemical polishing without power. It gives better performance on the surface shininess and for sure. Electropolishing is a non-mechanical polishing process, leaving no metal particle nor abrasiveness on the surface which otherwise occur easily during mechanical work. No dust or impurities will get sticked to the surface.

Clean room cleaning and packaging ensures each EP stainless steel tubing will be purged by several rounds of ultrasonic cleaning, capped and packaged in the clean room.

Where is EP Stainless Steel Tubing Needed?

Industries that have demanding requirements on tube internal wall thickness, mainly for roughness below 0.25um. BA stainless steel tubing can achieve a roughness around 0.4um. These fields need EP stainless steel tubing are as follow,

- • Pharmaceutical Industry

- • Food & Beverage

- • Pure Gas or Ultra-Pure Gas Transportation

- • High-end automobiles

- • Household & Industrial appliances

- • Semiconductor

EP Stainless Steel Tubing At CIVMATS

At CIVMATS, we produce stainless steel EP tubing with higher-than-average quality, approved with TUV test report at site. Apart from basic technical data being met, we have inhouse a series of test to ensure the best ever quality you'll get from China.

- • Roughness Test Equipment

- • Metalloscopy

- • Dew-point Instrument

- • Hardness Tester

- • Particle Counter

- • Scanning Electron Microscope

- • Energy Disperse Spectroscopy

- • Welding Test

- • UT Test

- • Pressure Test @ 3.0 MPA ~ 4.0 MPA

Welcome for your consultation for free! We expect to become your long-term business partner!