LNG Carriers are known as ships constructed for transportation of liquid natural gas (LNG). As more countries are attentive to use clean energy to reduce greenhouse gas emission, natural gas with its clean and environment friendly features are gaining increasing popularity in international market. Asia-pacific countries such as China, Japan, and South Korea are currently the largest consumers of LNG, but this market also keeps growing in North America and Europe for their pursuit of diversified energy source strategy. LNG carriers thus have massive untapped potential for the future.

There are three ways of transporting natural gas, i.e., pipelines, LNG carriers and compressed natural gas (CNG), among which pipelines still remain the mainstream, for the relatively lower construction and maintenance cost, as well as large transportation capacity over long distance. However, they are fixed in the installation places, lack of flexibility. CNG which involves compressing the gas to smaller volume to be stored in specialized tanks, also gains momentum with the growing demand for LNG, but it is limited to land transportation, restricting its wide popularity.

When it comes to LNG carrier, this transportation method also comes with its own benefits and costs. The first and foremost entry barrier is the huge cost. The expense involved for building, operating and maintaining a new LNG carrier can be hundreds of millions of dollars. Secondly, the construction of new LNG carriers takes a long time like 2.5 to 3 years. Thirdly, only a limited number of shipyards can deliver this kind of projects, such as Hudong Zhonghua, Hudong Zhonghui, Hyundai and Hyundai Mipo. Despite the limitations, LNG carriers still gain more popularity in the international trade of natural gases. According to the order book of LNG carriers, the number of newbuilding delivery comes from 54 in 2023, 83 in 2024, and a record 102 in 2025. The momentum of LNG carriers does not even stop there. Over 50 contracts associated with the construction of LNG carriers will be delivered in 2026 or later.

The increasing numbers are not unusual because the growing demand for cleaner and environment friendly energy meets the increasing global awareness and understanding of environment protection. LNG carriers can be classified into four types, namely, membrane type, moss type, self-supporting prismatic type and semi-membrane type, with the membrane type the most popular. Membrane-type LNG carriers are regarded as the most efficient and safest type of LNG carrier, as they provide excellent insulation to avoid leaks and spills. Meanwhile, they need less energy to store the cargo at desired temperatures. With the advancing technology driven by the buyers’ preference, membrane-type LNG are now becoming even safer and more efficient with reduced maintenance expenses, and greater cargo capacity. The semi-membrane type also gains more attention as they embody the advantages of membrane-type LNG while at the same time they provide greater cargo capacity.

According to the terminal distance, LNG carriers come in small-scale for short-haul routes, mid-scale for medium-haul routes and large-scale for long-haul routes. Generally speaking, the capacity of small-scale, mid-scale and large-scale LNG carriers can go up to 20,000m³, 20,000m³ ~ 40,000m³, and over 40,000m³ respectively. Various insulated tanks are assembled in LNG carriers and these tanks are mainly constructed with materials such as stainless steel and aluminum to resist extremely low temperatures (at -162°C) and high pressures. 316L stainless steel sheets are the most applied stainless steel materials, with TISCO brand highly recognizable in international market for the combined reasons of stainless steel sheet performance, super width without welding and price advantages in comparison with its international competitors.

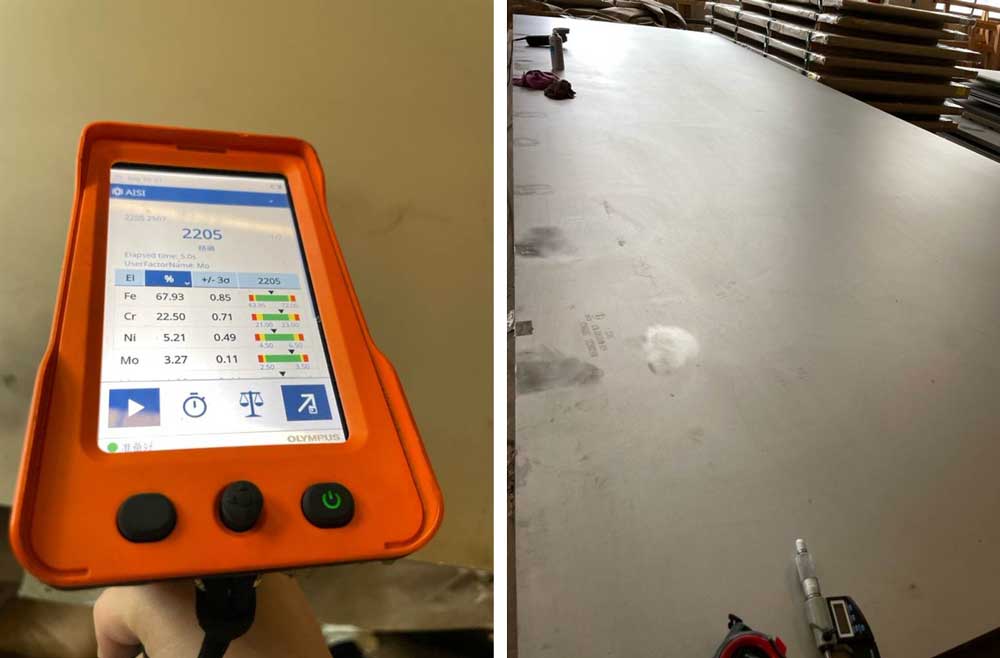

However, due to technology development the stainless steel materials made in China now enjoy better quality, yet at lower price in comparison with the scenario a decade ago. This means better quality of the same stainless steel sheet, or/and lower price for better stainless steel sheet. Nowadays, duplex 2205 stainless steel sheets come to be applied in LNG carriers, where 316L stainless steel sheets used to be considered the high-quality choice, thanks to the reduced material cost. As is known, 2205 stainless steel is superior to 316L in both corrosion resistance and mechanical properties. 2205 stainless steel are "duplex" because they embody the advantages of both austenitic stainless steel (excellent corrosion resistance) and ferritic stainless steel (outstanding mechanical properties, same weight with less material because 2205 has way higher tensile strength). The most recent case is the delivery of three LNG carriers equipped with 2205 duplex stainless steel LNG tanks. They are "XT 59" LNG carrier with a capacity of 9,050m³, "XT EXPLORATION" LNG carrier with a capacity of 15,200m³, and "XT 17" LNG carrier with a capacity of 4,300m³. The three ships are all owned by Xingtong Shipping Co., Ltd. with the handover ceremony held this August.

At CIVMATS, we stock and process famous brands stainless steel sheets, like TISCO, JISCO, BAOSTEEL, YONGJIN, TSINGSHAN, ZPSS, ZSESS etc. Below are our 2205 stainless steel plates exported to Korea for vessel building. In case of demands for stainless steel sheets, welcome for consultation. We are the best choice for you!